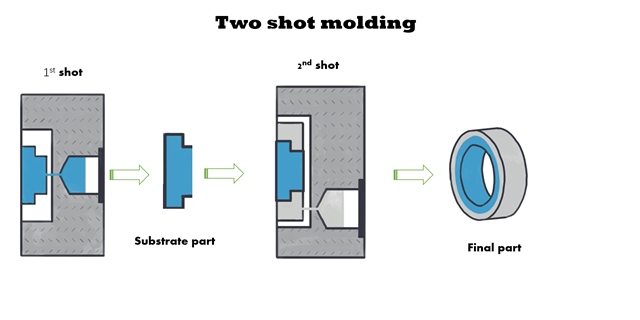

Did the title make you take a little guess? You can understand the overmoulding process with ease. Let us divide the two terms. “Over” can mean – one above the other. In this process, one or more components get moulded over the first layer of the mould. So, overmoulding is also known as two-shot moulding. In manufacturing terms, overmould gets considered as a two step process. In this blog, let us focus on the materials commonly utilised in overmoulding process.

Process:

The first step involves the moulding of the base component. This component is also referred to as substrate. It is then made to cool. The constituent materials are usually plastic. Then, the second layer gets laid on the first layers to create the end result. You can get the mould as per the need.

This process gets used to manufacture parts which include two materials. For example, toothbrush. Then the bottom layer is plastic and the top layer is rubber. The model gets designed so that you can hold the toothbrush with ease.

Benefits of Overmoulding Process:

Manufacturers of plastic products get many benefits from the overmoulding process. Overmoulding makes it possible to manufacture products consisting of various materials. It is also possible to produce overmoulds of different colours. Also, the process requires less working hours. There is no need for assembling products or machine equipment.

How the Materials Commonly Utilized in Overmoulding are Selected?

The major factor taken in consideration is the compatibility. Let us assume, the substrate and the second layer materials did not bond with each other. Then, the end result will be a weak product with less durability. The other problems can be

- Deformation in moulds

- A product with a low shelf life

- Complete process failure.

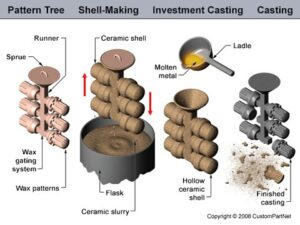

This image is taken from waykenrm.com

The overmoulding process consists of combinations (more than a thousand). It is the specialist engineers who select the materials. These specialists have to check the budget for the project and then decide on the materials. The factors they choose are innate properties, cost, appearance and bonding capabilities of the materials.

The commonly used materials in the overmoulding process are –

- SI (Silicone)

- ABS (Acrylonitrile Butadiene Styrene)

- TPR (Thermoplastic Rubber)

- HDPE (High-density Polyethylene)

- TPE (Thermoplastic Elastomers)

- PEEK (Polyether Ether Ketone)

- PP (Polypropylene)

- Nylon (Polyamide)

- PC (Polycarbonate)

- PMMA (Acrylic)

- PE (Polyethylene)

- PEI (Polyetherimide)

- POM (Polyoxymethylene)

- PBTR (Polybutylene Terephthalate)

- TPU (Thermoplastic Polyurethane)

Conclusion

As already mentioned, choosing materials commonly utilised in overmoulding (time-tested) is critical to a project’s success. But hold on; Are you interested in outsourcing the moulding process? Are you in the search for a company which has the best resin engineering specialists? Do you want them to help manufacture the product for your company? You can find the right project partner in custom manufacturing market places. These digital platforms will have a committed support team. They can help build strong partnerships with the companies you desire to work with. They can provide able guidance right from the initial stage to delivery of items.