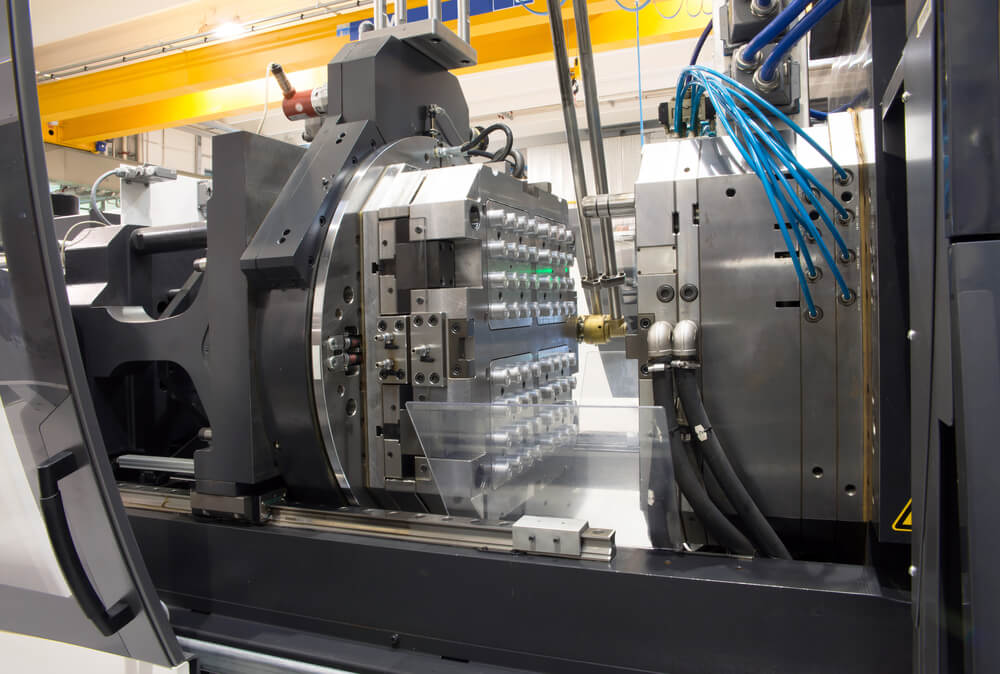

Metal Injection Moulding

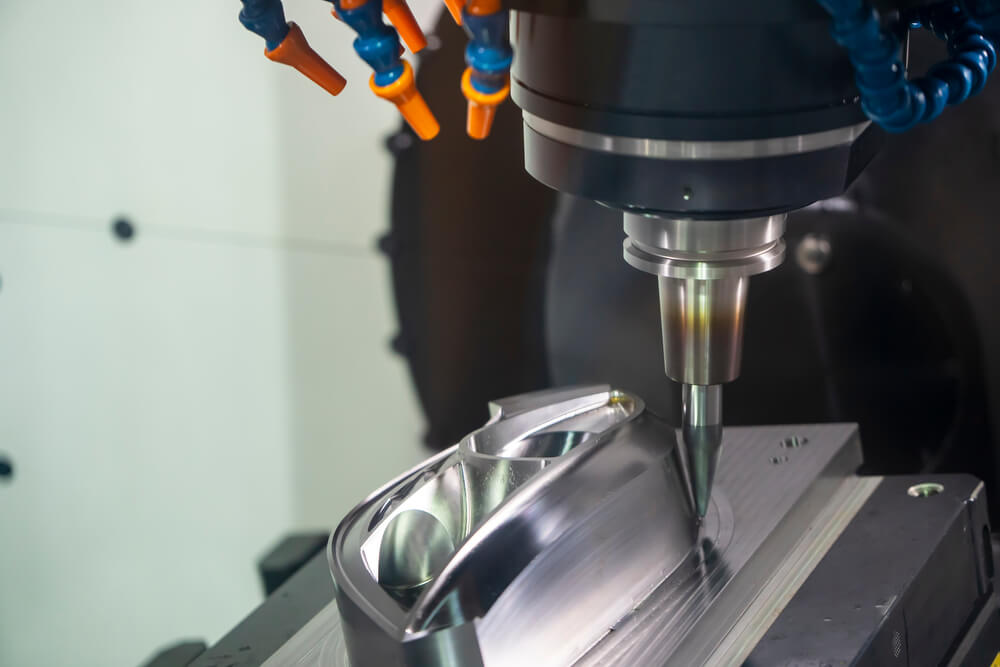

Our vendors provide multi-special metal injection moulding services in India to various industrial sectors at cost-effective rates. Armed with the recent machining software and high-end technology tools, our service providers are capable of preparing small, medium and even intricate metal injection moulding components (of different shapes, sizes and weights) that cater to industries such as sports, automotive, dental, medical and mobile phone.

They (metal injection moulding service providers in India) work on mainly ferrous and non-ferrous alloys, but if needed, can also work on other materials as per your need.