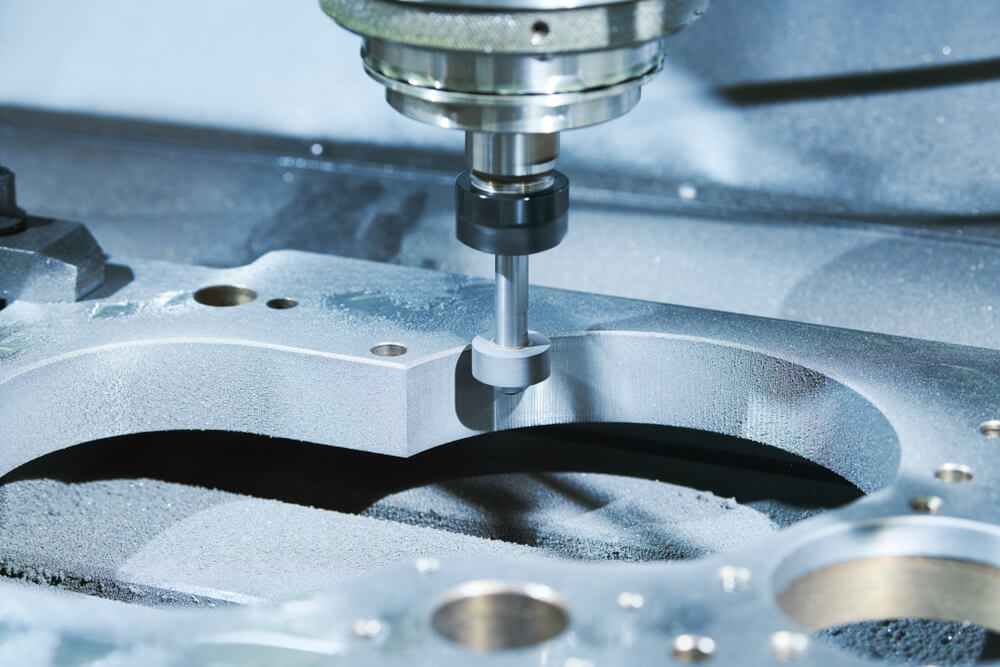

Fabrication

Vendosmart has, with great effort, established a database of verified and reputed fabrication service providers in India to cater to your needs. Browse through the profiles of hundreds to thousands of profiles of companies offering the best fabrication services in India.

Our fabrication service vendors have completed projects of complex designs and delivered them within the shipping date. Equipped with tools of manufacturing excellence, they do not have any reservations in working on MOQ projects to large scale production at the best prices in the market.